At I.F. Associates, we pride ourselves on delivering innovative solutions for consumer products. Our expertise lies in precision manufacturing, ensuring that every component meets the highest standards of quality and reliability. Whether it’s electronics, household appliances, or lifestyle gadgets, our plastic injection molding processes consistently deliver exceptional results.

Consumer Goods Plastic Injection Molding Company

We work closely with product designers, engineers, and manufacturers to create intricate components. Whether it’s a smartphone case or a kitchen appliance part, we understand the unique requirements of consumer goods. Our expertise lies in precision manufacturing, where attention to detail matters.

Our team selects optimal materials from a wide range of plastics, tailoring them to the specific needs of each consumer product. From concept to production, our end-to-end solutions adhere to the highest quality standards. Whether it’s enhancing the aesthetics of a lifestyle gadget or ensuring the durability of a household appliance, we’ve got you covered.

Markets We Serve

At I.F. Associates, we collaborate closely with our clients across diverse industries to create top-tier consumer products. Our commitment lies in tailoring solutions to specific applications, ensuring exceptional quality and functionality. Explore our range of offerings:

- Household Items

- Food and Beverage

- Cosmetics

- Lifestyle Gadgets

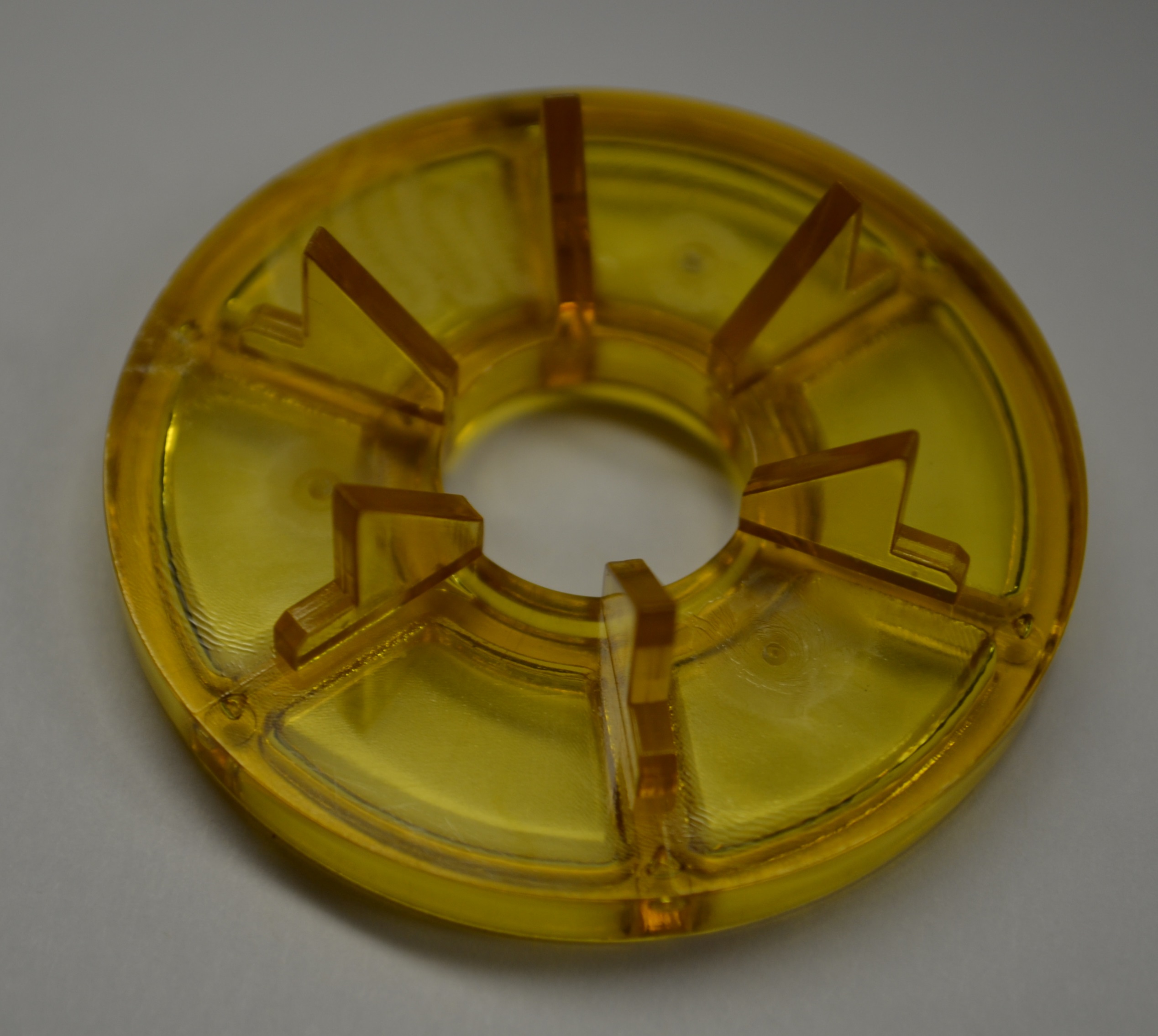

Our Selected Work

Industry Standard Materials We Use

I.F. Associates provides access to a comprehensive array of state-of-the-art thermoplastic options, aiding customers in selecting materials that precisely match the required performance characteristics for their finished parts, products, or assemblies.

Our customers benefit from a diverse selection of highly engineered materials, including:

- ABS – Acrylonitrile Butadiene Styrene

- PA – Nylon

- PBT – Polyester

- PC – Polycarbonate

- PEI – Ultem

- PET – Polyethylene

- PMMA – Acrylic

- POM – Acetal

- PP – Polypropylene

- PPE+PS – Polyphenylene Ether (Noryl)

- PUR – Polyurethane

- TPU/TPE – Thermoplastic Polyurethane

- LCP – Liquid crystal polymers

Quality Assurance and Quality Policy

At I.F. Associates, we prioritize quality assurance to ensure that every item we manufacture not only meets our clients’ standards but also complies with relevant regulations.

Our quality assurance department employs a range of techniques and tools for inspections, including:

| Equipment/Techniques | Description |

|---|---|

| Vision systems and Coordinate Measurement Machines (CMM) | Utilized for multi-sensor measurement during inspections. |

| Optical comparators with 16-inch screens | Used for detailed visual inspection and measurements. |

| Calibrated surface plates | Ensures accurate and precise measurements. |

| Gram scales, microscopes, gauge blocks, gauge pins, and digital calipers | Various tools are utilized for precise measurements and inspections. |

| Complete First Article Inspection (FAI) reports | Detailed reports are provided to validate the initial production run. |

| Advanced Quality Planning | Comprehensive planning processes to ensure quality throughout the manufacturing cycle. |

Our objective is to fortify our standing as leaders in quality by consistently meeting customer needs through ongoing enhancements to our plastic quality standards, service, and productivity. We place a strong emphasis on fulfilling requirements and maintaining an effective quality management system to ensure sustained excellence. Our company was built on this motto below and we live by this principle every day:

What our clients are saying?

"I.F. Associates has helped Practical Convenience to take the Easy Pouch product from concept to production. They partnered with us through the entire process, helping to bring our product to market. They have continued to support our success by scaling production to meet our needs and supply well-packaged products on-time and according to specifications to our distribution partners. We can always depend on the IFA team to work diligently to meet and exceed our demands."

Donna and MattPractical Convenience

I.F. Associates – Your Reliable Consumer Goods Plastic Injection Molding Company

The expertise and capabilities of a trusted plastic injection molding company like I.F. Associates are essential for supporting businesses by supplying them with dependable, high-quality consumer components crucial for delivering exceptional product experiences.

Why you should partner with us:

- Precision and Consistency: Our plastic injection molding ensures that every detail of your consumer products is crafted with precision and consistency. This means your items will function as intended.

- Material Quality: We use top-grade materials to produce consumer components, meeting stringent quality standards. This ensures that your products are safe for everyday use, minimizing any risks of harm or malfunction.

- Affordability: Injection molding offers a cost-effective solution for manufacturing consumer goods without compromising on quality. This means you get high-quality products at a price that suits your budget.

- Customization and Innovation: With our advanced molding techniques, we can bring your unique product ideas to life. Whether it’s a personalized design or an innovative feature, we can make it happen.

- Quality Assurance: I.F. Associates follows strict quality standards to ensure that your consumer components meet regulatory and industry standards.

- Timely Delivery: We understand the importance of getting your products to market quickly. That’s why we prioritize timely delivery, ensuring that you can meet consumer demand without delays.

Diverse Clients Trust I.F. Associates

Have a Project In Mind?