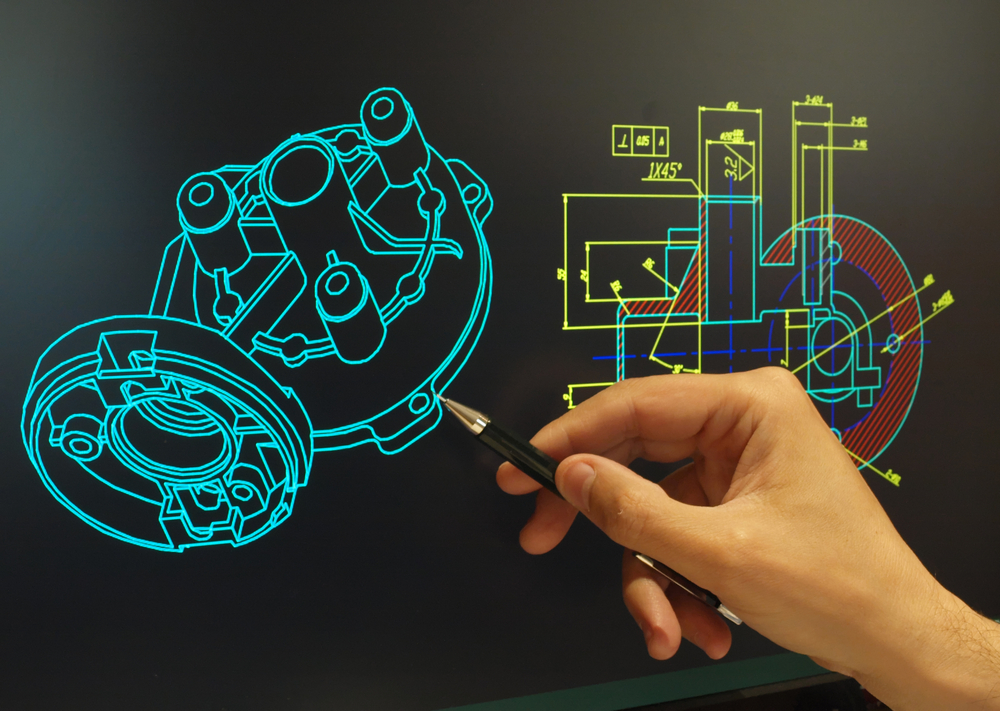

What is Design Engineering for Molded Prototypes?

Design engineering for molded prototypes involves creating preliminary plastic components and using injection molding techniques, for evaluation, testing, and validation purposes before full-scale production. This process typically encompasses several stages, from conceptualization and design refinement to the fabrication of physical prototypes.

It includes activities such as CAD modeling, mold design, material selection, and manufacturing process optimization to ensure that the prototype closely resembles the intended final product in terms of form, fit, and function.

Through meticulous iteration, molded prototypes are invaluable tools for assessing product performance and identifying design flaws. Here at I.F. Associates we also offer you plastic injection mold design services before finalizing the design for full-scale production.

Breathe life into your concepts.

Benefits of Design Engineering

| Aspect | With Design Engineering |

|---|---|

| Design Iteration | An iterative process involving feedback and refinement |

| Creativity | Encourages creative exploration and innovation |

| Problem-Solving | A systematic approach to identifying and solving challenges |

| Functionality | Emphasis on optimizing functionality and performance |

| Manufacturability | Designs optimized for ease of manufacturing |

| Validation | Prototypes tested and refined before production |

| Cost-effectiveness | Identifies cost-saving opportunities early on |

| Time-to-Market | Efficient process reduces time-to-market |

I.F. Associates is Here to Assist You

At I.F. Associates, our expertise spans various stages of product development, ensuring optimal results from initial design to distribution.

Our comprehensive approach includes:

- Design for Manufacturing: Our design engineers meticulously consider all aspects of injection mold requirements for your part.

- Plastic Injection Mold Design Services: We offer comprehensive design assistance, collaborating at any stage of your idea’s development.

- R&D of Plastic Parts: We specialize in researching and developing plastic components and welcome challenging projects.

- Patent Development: We assist inventors in patent development for their innovative products and solutions.

Based on our diversified experience, we partner with you to

- Accelerate the Design Process: We’ll help you fast-track your designs and speed up the product development cycle

- Offer Expert Product Development Support: We’re here to assist you with your product development challenges.

- Provide Integrated Design Solutions: Our team has experience integrating tooling and production requirements to complete your design on time and within budget.

Diverse Clients Trust I.F. Associates

Have a Project In Mind?