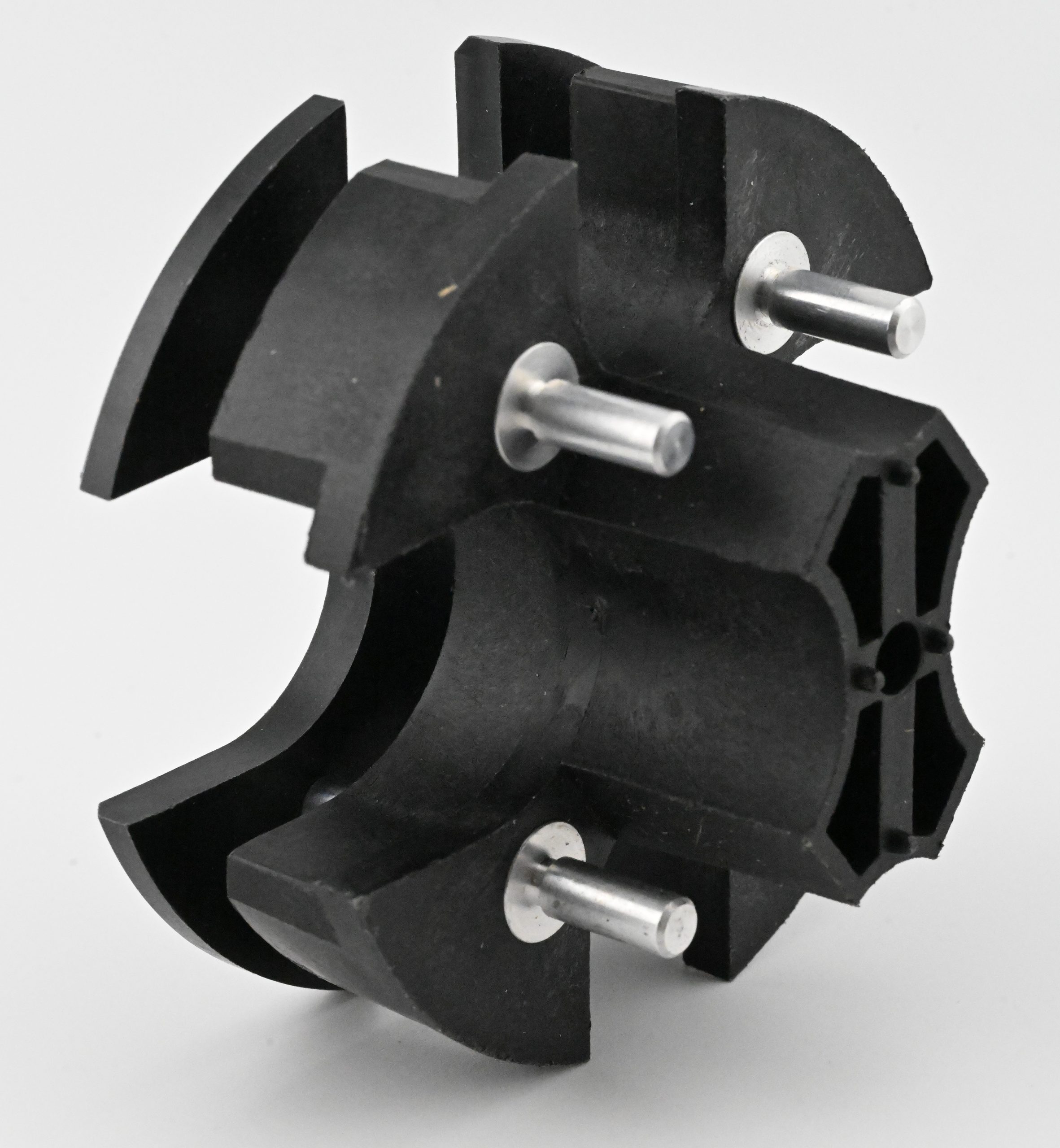

At I.F. Associates, we specialize in providing high-quality overmolding and insert molding services to meet your diverse manufacturing needs. Our techniques and equipment allow us to create complex, multi-material components with precision and efficiency. Whether you require enhanced functionality, improved aesthetics, or additional durability, our expert team is here to deliver exceptional results tailored to your specifications.

What is Overmolding and Insert Molding?

Overmolding

Comparison of Overmolding and Insert Molding

| Aspect | Overmolding | Insert Molding |

|---|---|---|

| Process Description | Molding one material over another | Encapsulating an insert within a plastic component |

| Typical Applications | Grips, seals, soft-touch surfaces | Reinforced components, conductive parts |

| Material Combinations | Thermoplastics with elastomers, multiple plastics | Metals, ceramics, plastics with thermoplastics |

| Benefits | Enhanced ergonomics, improved aesthetics | Increased strength, integrated functionality |

| Design Flexibility | High | High |

Key Benefits of Overmolding and Insert Molding

Our Overmolding and Insert Molding Capabilities

Our experienced engineering team collaborates with you throughout the design and production process, ensuring that your components are optimized for performance and manufacturability. We provide expert guidance on material selection, part design, and process optimization to achieve the best possible results.

Diverse Clients Trust I.F. Associates