Medical Plastic Injection Molding Company

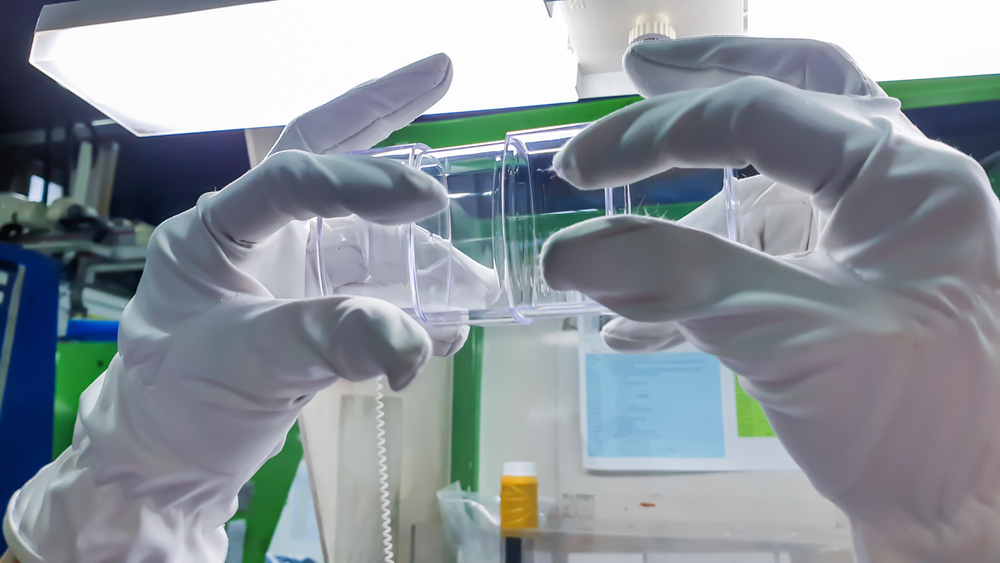

Our plastic injection molding processes guarantee consistent, high-quality medical device components. Plastic injection molding offers numerous advantages in the medical field, ensuring precision, consistency, and efficiency in manufacturing processes. For medical professionals, partnering with a reliable plastic injection molding company like I.F. Associates is paramount.

Medical Devices & Diagnostic Equipment Components

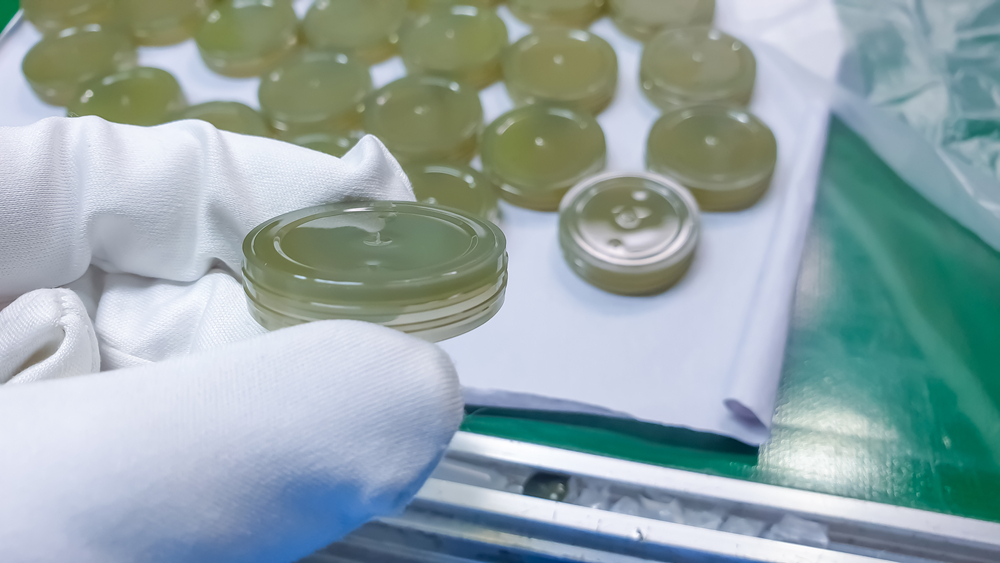

We use the latest technology to help you develop your ideas for medical devices and diagnostic equipment components, such as:

- Syringe assemblies

- Dental components

- Orthopedic parts and assemblies

- Medical packaging components

- Surgical devices

- Diagnostic components

Over the last few decades, we have built a reputation for being high-quality, dependable, and innovative

From concept to development to final product assembly, we can help you develop the medical devices and medical diagnostic equipment you specified – on time, with zero defects.

I.F. Associates – Your Reliable Medical Plastic Injection Molding Company

The expertise and capabilities of a trusted plastic injection molding company like I.F. Associates play a vital role in supporting medical professionals by providing them with reliable, high-quality components essential for delivering superior patient care.

Why you should partner with us:

Why you should partner with us:

- Precision and Consistency: Plastic injection molding produces intricate medical components with high precision and consistency — critical for proper functionality and patient safety.

- Material Compatibility: Medical-grade materials are molded to meet stringent regulatory requirements, ensuring compatibility with medical applications and minimizing contamination risks or adverse reactions.

- Cost-Effectiveness: Injection molding offers cost-effective solutions for producing medical components, keeping manufacturing expenses manageable without compromising quality or reliability.

- Customization and Innovation: With advanced molding techniques and tooling capabilities, plastic injection molding facilitates customization and innovation in medical device design.

- Regulatory Compliance: I.F. Associates adheres to stringent regulatory standards such as ISO 9001:2015, ISO 13485:2016, and FDA regulations, ensuring that medical components meet quality and safety requirements for regulatory approval and market acceptance.

- Reliability and Timeliness: I.F. Associates understands that timely delivery of high-quality medical components is critical to the continuity of patient care.

Diverse Clients Trust I.F. Associates

Have a Project In Mind?