We pride ourselves on the reliability of our plastic injection molding processes, which consistently deliver high-quality components for medical devices. Plastic injection molding proves indispensable in the medical sector with precision, consistency, and efficiency at the forefront. I.F. Associates stands out as the go-to choice for medical professionals seeking trusted partners.

Medical Plastic Injection Molding Company

At I.F. Associates, we specialize in delivering comprehensive solutions for the safe and cost-efficient production of a diverse array of precision medical components, devices, and assemblies. These vital products play a crucial role in medical, healthcare, and life sciences domains, enhancing patient care globally in hospital environments and at home.

Through our design and molding services, we create intricate products, collaborating closely with OEMs and Healthcare Professionals to select optimal materials from a wide spectrum of medical-grade plastics. Our offerings encompass a full suite of engineering and medical injection molding services. As an ISO-13485-certified facility, we also provide process validation services, ensuring adherence to rigorous quality and regulatory standards.

Markets We Serve

In collaboration with our clients, spanning various medical, life sciences, and healthcare sectors, I.F. Associates is dedicated to producing top-tier products tailored to specific applications, including:

- Medical Device

- Medical Disposable and Diagnostic

- Fluid and Drug Delivery

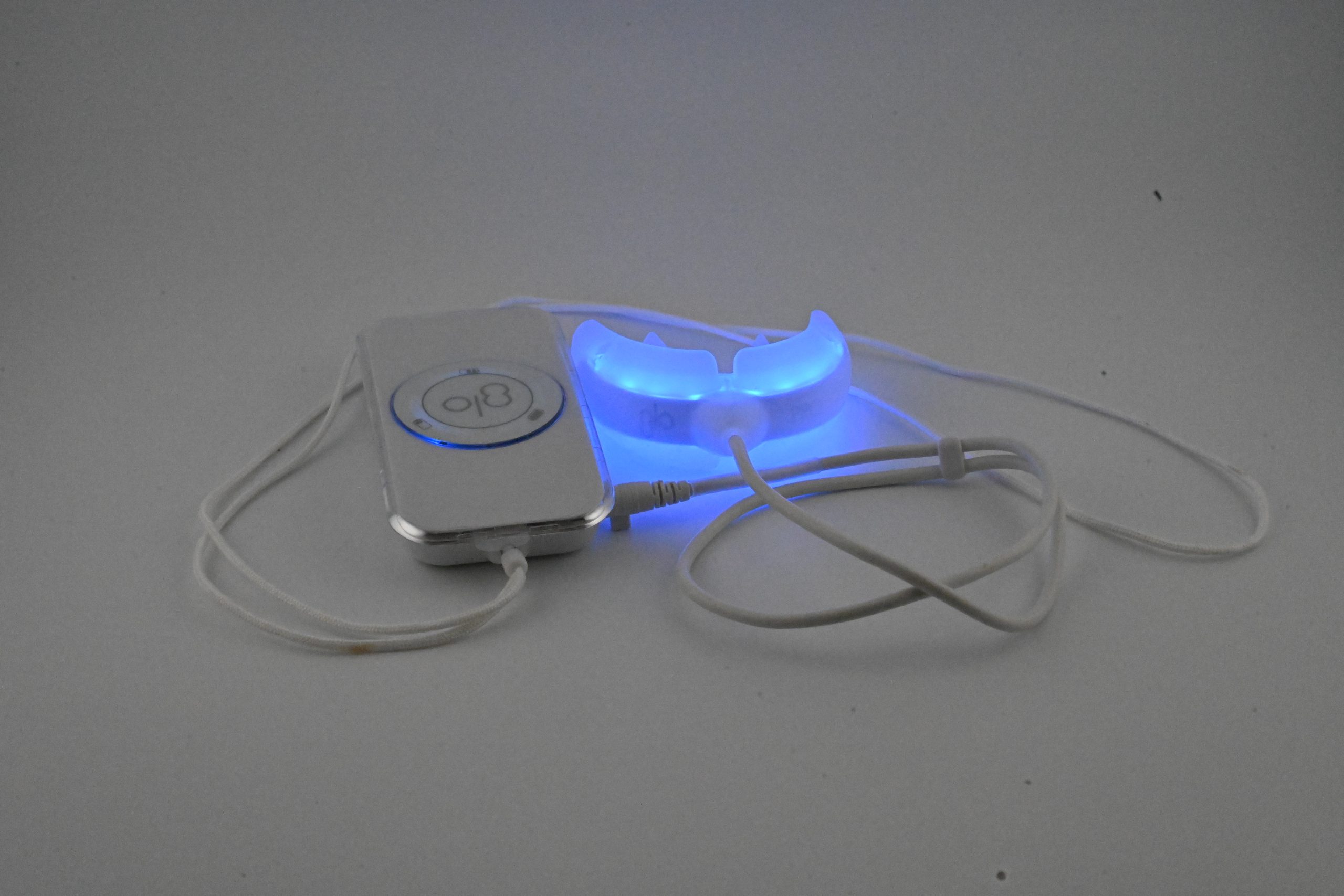

- Dental Components

- Minimally Invasive Surgical Components

Our Selected Work

Medical Grade Materials We Use

I.F. Associates provides access to a comprehensive array of state-of-the-art thermoplastic options, aiding customers in selecting materials that precisely match the required performance characteristics for their finished parts, products, or assemblies.

Our customers benefit from a diverse selection of highly engineered materials, including:

- ABS – Acrylonitrile Butadiene Styrene

- PA – Nylon

- PBT – Polyester

- PC – Polycarbonate

- PEI – Ultem

- PET – Polyethylene

- PMMA – Acrylic

- POM – Acetal

- PP – Polypropylene

- PPE+PS – Polyphenylene Ether (Noryl)

- PUR – Polyurethane

- TPU/TPE – Thermoplastic Polyurethane

- LCP – Liquid crystal polymers

Quality Assurance and Quality Policy

At I.F. Associates, we prioritize quality assurance to ensure that every item we manufacture not only meets our clients’ standards but also complies with relevant regulations.

Our quality assurance department employs a range of techniques and tools for inspections, including:

| Equipment/Techniques | Description |

|---|---|

| Vision systems and Coordinate Measurement Machines (CMM) | Utilized for multi-sensor measurement during inspections. |

| Optical comparators with 16-inch screens | Used for detailed visual inspection and measurements. |

| Calibrated surface plates | Ensures accurate and precise measurements. |

| Gram scales, microscopes, gauge blocks, gauge pins, and digital calipers | Various tools are utilized for precise measurements and inspections. |

| Complete First Article Inspection (FAI) reports | Detailed reports are provided to validate the initial production run. |

| Advanced Quality Planning | Comprehensive planning processes to ensure quality throughout the manufacturing cycle. |

| Process Validations (IQ, OQ, PQ) | Validation processes including Installation Qualification (IQ), Operational Qualification (OQ), and Performance Qualification (PQ) to ensure processes meet requirements. |

Our objective is to fortify our standing as leaders in quality by consistently meeting customer needs through ongoing enhancements to our plastic quality standards, service, and productivity. We place a strong emphasis on fulfilling requirements and maintaining an effective quality management system to ensure sustained excellence. Our company was built on this motto below and we live by this principle every day:

What our clients are saying?

"IFA continues to be an excellent supplier. The cooperation and support given, from initial design through production and shipment, has been terrific. The input from their team members has kept our project moving and has helped us avoid several pitfalls in part design and subsequent mold fabrication. IFA is a trusted partner and will remain a highly valued supplier of medical device components."

Scott VernerCOO ONY Biotech

I.F. Associates – Your Reliable Medical Plastic Injection Molding Company

The expertise and capabilities of a trusted plastic injection molding company like I.F. Associates play a vital role in supporting medical professionals by providing them with reliable, high-quality components essential for delivering superior patient care.

Why you should partner with us:

- Precision and Consistency: Plastic injection molding produces intricate medical components with high precision and consistency — critical for proper functionality and patient safety.

- Material Compatibility: Medical-grade materials are molded to meet stringent regulatory requirements, ensuring compatibility with medical applications and minimizing contamination risks or adverse reactions.

- Cost-Effectiveness: Injection molding offers cost-effective solutions for producing medical components, keeping manufacturing expenses manageable without compromising quality or reliability.

- Customization and Innovation: With advanced molding techniques and tooling capabilities, plastic injection molding facilitates customization and innovation in medical device design.

- Regulatory Compliance: I.F. Associates adheres to stringent regulatory standards such as ISO 9001:2015, ISO 13485:2016, and FDA regulations, ensuring that medical components meet quality and safety requirements for regulatory approval and market acceptance.

- Reliability and Timeliness: I.F. Associates understands that timely delivery of high-quality medical components is critical to the continuity of patient care.

Diverse Clients Trust I.F. Associates

Have a Project In Mind?